Production

ALL Circuits' expertise is based on the latest generation of equipment and a management system inherited from the culture of zero defect, making it possible to meet all your needs for small, medium and large production runs.

Back-end manufacturing

All-in-one

SMT lines

Digital monitoring

Complete traceability

Compliance with standards

All-in-one SMT lines

• Smaller and smaller and exotic components

• ISP slavery and screen printing

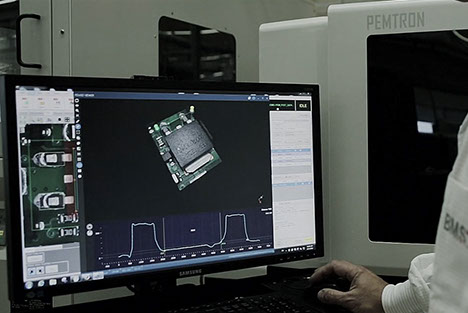

• 3D AOI, ICT and online programmer

• Cobot and robot cells

• Automatic stripping and packaging

• On-line PCB marking and traceability

• Complete traceability for each component

Cutting-edge technology >>

Flexible real-time traceability and monitoring >>

Back-End

Fully automated

Generic or dedicated assembly lines •

Manual, semi-automatic •

or 100% automatic assembly

Expertise •

in assembly

screwing, gluing,

varnishing,

classic/selective wave

Workshop •

Final assembly •

Tests •

Production cells •

Dedicated team per customer •

<< Solutions tailored to your needs

<< Dedicated tools

Digital monitoring

Traceability •

Material management •

ERP integration •

Intelligent machines •

Data control •

Self-monitoring at every step •

Compliance with

standards

• IATF 16949

• ISO 14001

• ISO 9001

• ISO 13485

• ISO 45001

• UL 94

• IPC 610 class 3 standard

• 3 Process brasage WEEE/RoHs, JEDEC

Complete traceability

Poka Yoke •

Production monitoring •

IMEI, SN, PN, MAC address •

FPY testers •

After-Sales Service and Customer Returns •

Packaging •

ERP link •

Product life tracking •

Secure data •

ALL Circuits'

+

EXTRAS

ESD access control

Flexibility and versatility: small, medium and large series production based on pull flow mode with a high level of productivity

Mastery of products with multiple sub-assemblies: PCBA, mechanical, plastic, cables, etc.

Smart factory : placement precision, MtoM communication, best-in-class equipment

Expertise in process automation and manufacturing technologies and traceability management

Cost effective manufacturing

High mix, high volume

Automotive methodology, quality culture

A production schedule linked to customer service

for better reactivity

QRQC management system

Technical process documentation and manufacturing instructions

Lean manufacturing

Incident management and securisation of your production

Zero

defect culture

ALL Circuits

Intelligent Manufacturing Services

In a few figures

Our 4 core businesses

Markets

Locations

News

We are ALL Circuits

© ALL Circuits 2020

All rights reserved